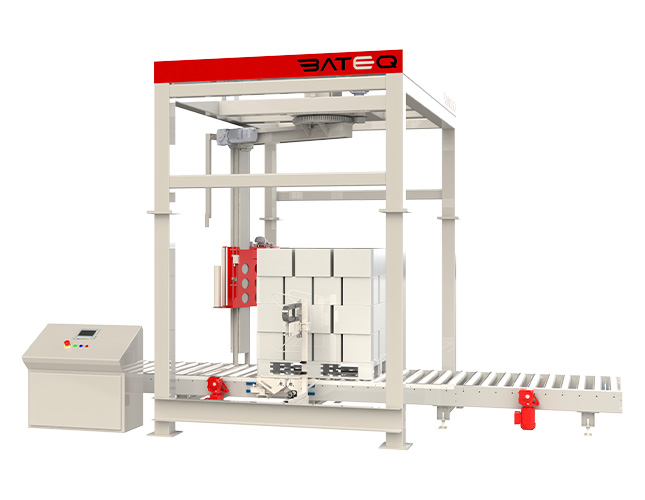

Pallet Stretch film wrapper

BRFW-70

The advantages

- Wraps pallets with stretch film at high speed

- The rotary arm is equipped with a heavy-duty turntable and therefore requires virtually no maintenance

- Saves on stretch film use

- The number of windings is manually adjustable

- No more semi-wrapped pallets due to the automatic film break and end roll detection

- Dimensions of film roll Ø300mm, with a core diameter of 76mm and a length of up to 500mm

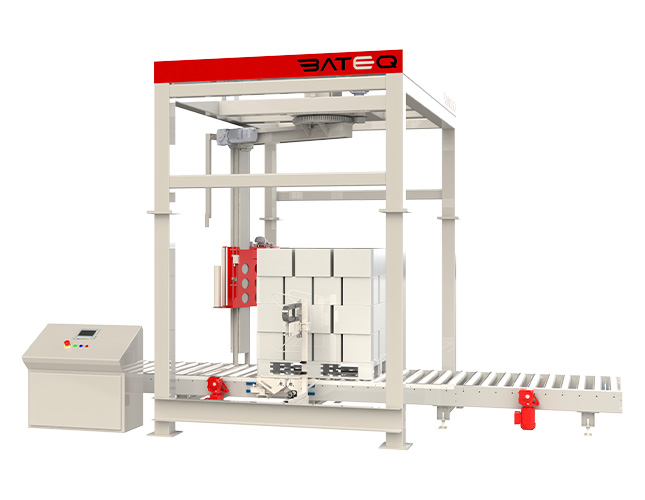

Pallet Stretch film wrapper BRFW-70

The advantages

- Wraps pallets with stretch film at high speed

- The rotary arm is equipped with a heavy-duty turntable and therefore requires virtually no maintenance

- Saves on stretch film use

- The number of windings is manually adjustable

- No more semi-wrapped pallets due to the automatic film break and end roll detection

- Dimensions of film roll Ø300mm, with a core diameter of 76mm and a length of up to 500mm

Wrapping pallets fully automatically

This machine wraps fully automatic pallets which are feed on the pallet rollerconveyor under the wrapper. The wrapper consists of a 4-column steel frame which is secured by a slewing ring which is mounted on the rotation arm. This rotation arm is provided with a cutting device and a sealing unit that fixes the film after it has been cut. This prevents the problem of loose hanging foil ends.

The film clamp clamps the film and after the preset number of windings, the cutting device cuts the film to the desired length.

The wrapping machine is equipped with a powered “pre-stretch” unit that can give a stretch of up to ± 350% on the foil. This can result in a considerable saving on the annual use of stretch film. Moreover, this results in a nice, tight end result, which radiates quality.

The pallet height is scanned with a photocell that automatically stops the wrapper, the number of top and bottom windings is manual adjustable.

For the unlikely event that the film tears, an automatic film break detection is provided that stops the wrapper in the event of a break and turns it to its starting position.

wrapping pallets fully automatically

This machine wraps fully automatic pallets which are feed on the pallet rollerconveyor under the wrapper. The wrapper consists of a 4-column steel frame which is secured by a slewing ring which is mounted on the rotation arm. This rotation arm is provided with a cutting device and a sealing unit that fixes the film after it has been cut. This prevents the problem of loose hanging foil ends.

The film clamp clamps the film and after the preset number of windings, the cutting device cuts the film to the desired length.

The wrapping machine is equipped with a powered “pre-stretch” unit that can give a stretch of up to ± 350% on the foil. This can result in a considerable saving on the annual use of stretch film. Moreover, this results in a nice, tight end result, which radiates quality.

The pallet height is scanned with a photocell that automatically stops the wrapper, the number of top and bottom windings is manual adjustable.

For the unlikely event that the film tears, an automatic film break detection is provided that stops the wrapper in the event of a break and turns it to its starting position.

Request a free quote

REQUEST ADVICE?

ASK A

QUESTION?

CALL WITH

BATEQ?

REQUEST ADVICE?

ASK A

QUESTION?

CALL WITH

BATEQ?

Information?

Information?