See flexibility, razendsnel

and a publishing house

etc. production costs

Product automation with the aid of robots is a revolutionary manner that never takes away the thinking that is based on the previous product processes. A robot has a wide range of flexibility, with a special design that can handle a variety of different products and can be used in multiple ways.

For the mechanisation of a repetitive process, the use of one or more industrial robots is often a good solution. Especially when such robot technology is combined with other machines and supply/discharge systems.

The best solutions

for your product environment

Whether the use of a robot-controlled solution is interesting depends on many factors. We would be happy to discuss with you and see together which solution best suits your production environment and how we can organize it even more efficiently.

BATEQ is an independent robot integrator, we are not brand tied, our goal is to ultimately realize the best solution for our client.

Advantages of robot handling systems

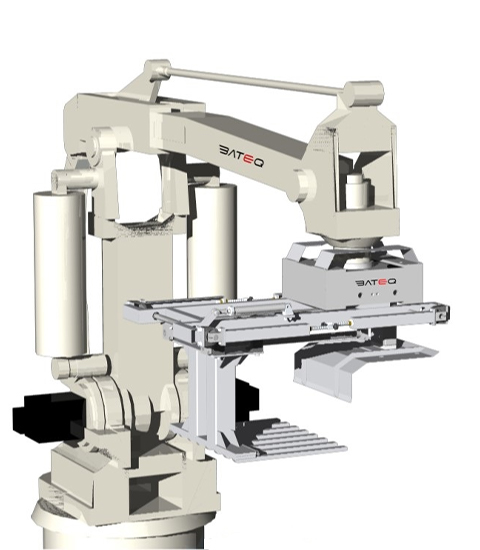

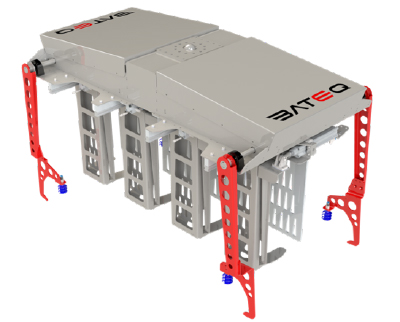

Gripper technique

Unique modular concept can be integrated into any system

BATEQ has developed a unique modular concept that allows us to move a very wide variety of products. These grippers can be integrated into almost any system and can be used with any brand.

A high degree of flexibility and versatility are characteristic of our grippers, pallets, boxes, crates, bags, cans and/or other products can be moved effortlessly.

We take on almost every challenge, it only becomes really interesting for us if a base or intermediate sheet is also placed, this is also possible.

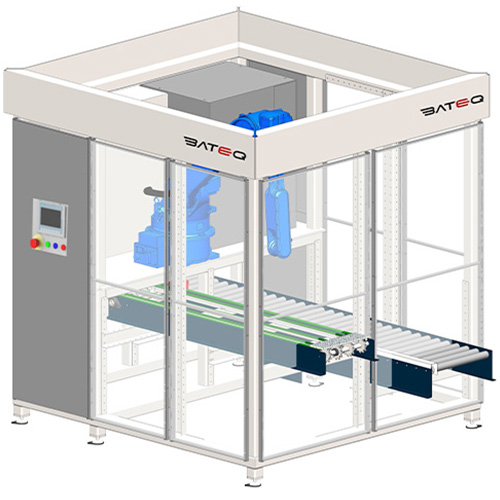

Pick & place units

Technology for fast, safe and precise positioning

Fast, safe and precise positioning, these are the qualifications that match our Pick & Place robot solutions. Smart technology summarized in a compact and safely shielded housing. With increasing e-commerce transactions and other complex operations and the shortage of good, motivated people, this robot can offer a solution. A Cobot is perhaps a better term because the machine is intended to work together with people.

AGV’s – Automated Guided Verhicles

Flexibility and convenience for internal transport

Automation of systems is not only reserved for robot solutions. The market for AGVs (Automated Guided Vehicles) is also booming.

BATEQ also has AGV solutions for the internal transport of products. Together with our partner we can collect and deliver pallets, rolling containers, crates, boxes and other load carriers.

The modular structure, flexibility and ease of use are the core competencies of this system.

Where previously AGVs followed fixed routes along wires and magnets, the newer systems have a varied range of control techniques such as laser, distance measuring, mapping and data storage.

AGVs are becoming increasingly smarter and can now also lift the goods they move, which makes them a lot more interesting. Especially for bridging longer distances and where products also have to be picked up and/or dropped off.

Information?

Information?